Привет народ, хочу рассказать про TMC2209 BIGTREETECH v1.2 UART, ramps 1.4, arduino DUE и klipper, возможно эта информация будет кому нибудь полезна:

Для начала расскажу про свое оборудование:

1. Ramps 1.4 переделанный под arduino due + отдельная силовая плата с оптической развязкой...

2. Дисплей

RepRapDiscount Smart Controller

3. Кинематика каретки h-bot, привод стола через ходовой винт с шагом 8 мм

4. Управляет всем этим orangepi pc+ под управлением armbian и octoprint//

Спойлер

Предыстория

Недавно достались мне TMC2209 BIGTREETECH v1.2 UART

Возникла мысль сделать стол с автоматической калибровкой (гугли stallGuard), но из за недостаточной жесткости механизма перемещения головки, а также из за привода стола (ходовой винт) эта затея потерпела неудачу.

Ну и судя по отзывам в сети, народ не рекомендует делать калибровку стола с использованием технологии stallGuard

Раньше ипользовал Repetier но т.к. он не поддерживает tmc2209 в режиме UART - решил перейти на Klipper...

Спойлер

Проблемы

1. Klipper позволяет прошить due через programming port(repetier у меня работал только через programming port), но не хочет подключаться к плате после прошивки..

- проблему удалось решить подключив DUE через

Native USB...

2.

Klipper требует доработки китайской arduino due

Решил применить TMC2209 в режиме UART на оси X и Y с применением технологии stallGuard (без концевиков)

Спойлер

TMC2209 BIGTREETECH v1.2 UART

1. Arduino due имеет 4 uart порта

- 0 порт отвечает за связь (выводы ar0, ar1)

- 2 порт занят дисплеем

- остаются 1 и 3 порты, это соответственно ar14, ar15 и ar18, ar19

На 1 и 3 порты и будем вешать связь с драйверами двигателей Х и Y.

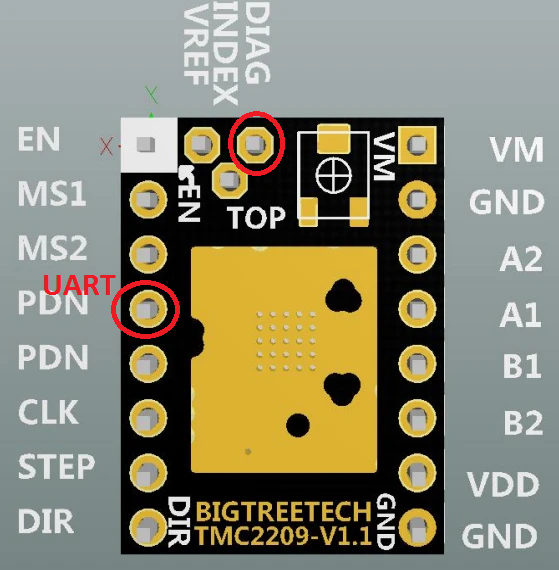

2. Чтобы реализовать виртуальные концевики нужно ножку diag tmc2209 подсоединить к due (см. параметр diag_pin в printer.cfg) и соответственно ногу UART присоединить к одному из портов UART due (к ноге rx)

Никаких переходников с резистором (как в marlin) паять не нужно, просто напрямую 1 проводом подсоединяем ногу UART TMC2209 к ноге RX due, и ногу DIAG TMC2209 на свободную ногу контроллера.

- tmc2209-BIGTREETECH-v1.1-pin-map

- tmc2209_pin_map.png (285.41 КБ) 4632 просмотра

Изображение подходит и к версии 1.2 от BIGTREETECH

Положение порта UART может меняться,

см. раздел 8.1 мануала

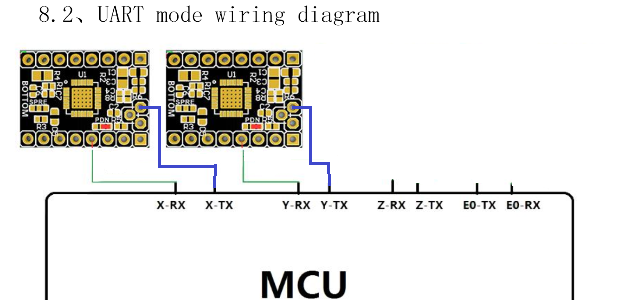

п.с в разделе 8.2 показана схема подключения драйвера к контроллеру (эта схема актуальна для Marlin 2.0) схема для klipper ниже:

- Подключение к Due

- tmc2209_connection.png (111.68 КБ) 4632 просмотра

Синий провод это подключение ноги DIAG TMC2209 к контроллеру (нужно для работы виртуальных концевиков, в работе UART не учавствует, подкючать к пину Tx не обязательно, можно к любому другому свободному)

Итак, в моем случае подключение выглядит так:

Двигатель Х

Двигатель Y

Ну и еще остается место для 2 концевиков, ниже приведу полный конфиг Klipper...

Собственно на этом подключение закончено...

Настройка klipper на работу с TMC 2209

Спойлер

Для работы TMC 2209 в режиме Uart в Klipper я указал следующие параметры(на примере двигателя X, для Y полностью аналогично, см. полный конфиг ниже)

1. вводим секцию [tmc2209 stepper_x]

Код: Выделить всё

[tmc2209 stepper_x]

uart_pin: ar15 #Y-max-endstop

microsteps: 16

run_current: 0.4

hold_current: 0.3

stealthchop_threshold: 100

interpolate: true

driver_SGTHRS: 75 # чувствительность [0:255], 0-наименее чувствительный

diag_pin: ^ar14 # нога контроллера к которой подключен DIAG вывод TMC2209 (см. изображение выше)

sense_resistor: 0.110

Особо стоит отметить параметр driver_SGTHRS это чувствительность драйвера - "чувствительность виртуального концевика", настраивается индивидуально(0- выключено, 255 - очень чувствительный).

2. В разделе [stepper_x]

Код: Выделить всё

[stepper_x]

step_pin: ar54

dir_pin: ar55

enable_pin: !ar38

step_distance: 0.0125

[b]endstop_pin: tmc2209_stepper_x:virtual_endstop[/b]

position_endstop: 0

position_min: 0

position_max: 210

homing_speed: 50

homing_positive_dir: false

В общем то на это настройка звершена...

И можно пробовать...

Ниже приведен мой полный рабочий конфиг

Спойлер

printer.cfg

Код: Выделить всё

# This file serves as documentation for config parameters. One may

# copy and edit this file to configure a new cartesian style

# printer. For delta style printers, see the "example-delta.cfg"

# file. For corexy/h-bot style printers, see the "example-corexy.cfg"

# file. Only common config sections are described here - see the

# "example-extras.cfg" file for configuring less common devices.

# DO NOT COPY THIS FILE WITHOUT CAREFULLY READING AND UPDATING IT

# FIRST. Incorrectly configured parameters may cause damage.

# A note on pin names: pins may be configured with a hardware name

# (such as "PA4") or with an Arduino alias name (such as "ar29" or

# "analog3"). In order to use Arduino names, the pin_map variable in

# the mcu section must be present and have a value of "arduino". Pin

# names may be preceded by an '!' to indicate that a reverse polarity

# should be used (eg, trigger on low instead of high). Input pins may

# be preceded by a '^' to indicate that a hardware pull-up resistor

# should be enabled for the pin. If the micro-controller supports

# pull-down resistors then an input pin may alternatively be preceded

# by a '~'.

# Micro-controller information.

[mcu]

serial: /dev/serial/by-id/usb-Klipper_sam3x8e_20312051503038383232303231303139-if00

pin_map: arduino

baud: 115200

[tmc2209 stepper_x]

uart_pin: ar15 #Y-max-endstop

microsteps: 16

run_current: 0.4

hold_current: 0.3

stealthchop_threshold: 100

interpolate: true

driver_SGTHRS: 75 # чувствительность [0:255], 0-наименее чувствительный

diag_pin: ^ar14

sense_resistor: 0.110

[tmc2209 stepper_y]

uart_pin: ar19 #Z-max-endstop

microsteps: 16

run_current: 0.4

hold_current: 0.3

stealthchop_threshold: 100

interpolate: true

driver_SGTHRS: 75 # чувствительность [0:255], 0-наименее чувствительный

diag_pin: ^ar18

sense_resistor: 0.110

#[probe]

#pin: tmc2209_stepper_z:virtual_endstop

#z_offset: 0

# The stepper_x section is used to describe the stepper controlling

# the X axis in a cartesian robot.

[stepper_x]

step_pin: ar54

dir_pin: ar55

enable_pin: !ar38

step_distance: 0.0125

endstop_pin: tmc2209_stepper_x:virtual_endstop

position_endstop: 0

position_min: 0

position_max: 210

homing_speed: 50

homing_positive_dir: false

# The stepper_y section is used to describe the stepper controlling

# the Y axis in a cartesian robot. It has the same settings as the

# stepper_x section.

[stepper_y]

step_pin: ar60

dir_pin: !ar61

enable_pin: !ar56

step_distance: 0.0125

#endstop_pin: ^!ar3 # x-min

endstop_pin: tmc2209_stepper_y:virtual_endstop

position_endstop: 0

position_max: 210

homing_speed: 50

homing_positive_dir: false

# The stepper_z section is used to describe the stepper controlling

# the Z axis in a cartesian robot. It has the same settings as the

# stepper_x section.

[stepper_z]

step_pin: ar46

dir_pin: !ar48

enable_pin: !ar62

step_distance: 0.000625

endstop_pin: ^ar2

#endstop_pin: tmc2209_stepper_z:virtual_endstop

#endstop_pin:^ar2

position_endstop: 209.7

position_min: 0

position_max: 210.7

homing_speed: 50

[adc_temperature my_thermistor]

temperature1: 20

resistance1: 94000

temperature2: 50

resistance2: 36800

temperature3: 70

resistance3: 15400

temperature4: 90

resistance4: 8270

temperature5: 100

resistance5: 6920

temperature6: 110

resistance6: 5690

temperature7: 120

resistance7: 4990

temperature8: 130

resistance8: 4285

temperature9: 140

resistance9: 3700

temperature10: 150

resistance10: 3370

temperature11: 170

resistance11: 2840

temperature12: 190

resistance12: 2555

temperature13: 210

resistance13: 2410

temperature14: 230

resistance14: 2300

temperature15: 250

resistance15: 2220

# The extruder section is used to describe both the stepper

# controlling the printer extruder and the heater parameters for the

# nozzle. The stepper configuration has the same settings as the

# stepper_x section and the heater configuration has the same settings

# as the heater_bed section (described below).

[extruder]

step_pin: ar26

dir_pin: !ar28

enable_pin: !ar24

step_distance: 0.0056124923077

nozzle_diameter: 0.400

# Diameter of the nozzle orifice (in mm). This parameter must be

# provided.

filament_diameter: 1.7500

# The nominal diameter of the raw filament (in mm) as it enters the

# extruder. This parameter must be provided.

#max_extrude_cross_section:

# Maximum area (in mm^2) of an extrusion cross section (eg,

# extrusion width multiplied by layer height). This setting prevents

# excessive amounts of extrusion during relatively small XY moves.

# If a move requests an extrusion rate that would exceed this value

# it will cause an error to be returned. The default is: 4.0 *

# nozzle_diameter^2

#instantaneous_corner_velocity: 1.000

# The maximum instantaneous velocity change (in mm/s) of the

# extruder during the junction of two moves. The default is 1mm/s.

#max_extrude_only_distance: 50.0

# Maximum length (in mm of raw filament) that a retraction or

# extrude-only move may have. If a retraction or extrude-only move

# requests a distance greater than this value it will cause an error

# to be returned. The default is 50mm.

#max_extrude_only_velocity:

#max_extrude_only_accel:

# Maximum velocity (in mm/s) and acceleration (in mm/s^2) of the

# extruder motor for retractions and extrude-only moves. These

# settings do not have any impact on normal printing moves. If not

# specified then they are calculated to match the limit an XY

# printing move with a cross section of 4.0*nozzle_diameter^2 would

# have.

#pressure_advance: 0.0

# The amount of raw filament to push into the extruder during

# extruder acceleration. An equal amount of filament is retracted

# during deceleration. It is measured in millimeters per

# millimeter/second. The default is 0, which disables pressure

# advance.

#pressure_advance_smooth_time: 0.040

# A time range (in seconds) to use when calculating the average

# extruder velocity for pressure advance. A larger value results in

# smoother extruder movements. This parameter may not exceed 200ms.

# This setting only applies if pressure_advance is non-zero. The

# default is 0.040 (40 milliseconds).

#

# The remaining variables describe the extruder heater.

heater_pin: ar59

# PWM output pin controlling the heater. This parameter must be

# provided.

#max_power: 1.0

# The maximum power (expressed as a value from 0.0 to 1.0) that the

# heater_pin may be set to. The value 1.0 allows the pin to be set

# fully enabled for extended periods, while a value of 0.5 would

# allow the pin to be enabled for no more than half the time. This

# setting may be used to limit the total power output (over extended

# periods) to the heater. The default is 1.0.

sensor_type: my_thermistor

# Type of sensor - common thermistors are "EPCOS 100K B57560G104F",

# "ATC Semitec 104GT-2", "NTC 100K beta 3950", "Honeywell 100K

# 135-104LAG-J01", and "NTC 100K MGB18-104F39050L32". See the

# example-extras.cfg file for other sensors. This parameter must be

# provided.

sensor_pin: analog9

# Analog input pin connected to the sensor. This parameter must be

# provided.

pullup_resistor: 4700

# The resistance (in ohms) of the pullup attached to the thermistor.

# This parameter is only valid when the sensor is a thermistor. The

# default is 4700 ohms.

#inline_resistor: 4700

# The resistance (in ohms) of an extra (not heat varying) resistor

# that is placed inline with the thermistor. It is rare to set this.

# This parameter is only valid when the sensor is a thermistor. The

# default is 0 ohms.

#smooth_time: 2.0

# A time value (in seconds) over which temperature measurements will

# be smoothed to reduce the impact of measurement noise. The default

# is 2 seconds.

control: pid

# Control algorithm (either pid or watermark). This parameter must

# be provided.

pid_Kp: 34.542

# Kp is the "proportional" constant for the pid. This parameter must

# be provided for PID heaters.

pid_Ki: 1.599

# Ki is the "integral" constant for the pid. This parameter must be

# provided for PID heaters.

pid_Kd: 186.528

# Kd is the "derivative" constant for the pid. This parameter must

# be provided for PID heaters.

#pid_integral_max:

# The maximum "windup" the integral term may accumulate. The default

# is to use the same value as max_power.

#pwm_cycle_time: 0.100

# Time in seconds for each software PWM cycle of the heater. It is

# not recommended to set this unless there is an electrical

# requirement to switch the heater faster than 10 times a second.

# The default is 0.100 seconds.

#min_extrude_temp: 170

# The minimum temperature (in Celsius) at which extruder move

# commands may be issued. The default is 170 Celsius.

min_temp: 0

max_temp: 235

# The maximum range of valid temperatures (in Celsius) that the

# heater must remain within. This controls a safety feature

# implemented in the micro-controller code - should the measured

# temperature ever fall outside this range then the micro-controller

# will go into a shutdown state. This check can help detect some

# heater and sensor hardware failures. Set this range just wide

# enough so that reasonable temperatures do not result in an

# error. These parameters must be provided.

# The heater_bed section describes a heated bed (if present - omit

# section if not present).

[heater_bed]

heater_pin: ar66

sensor_type: EPCOS 100K B57560G104F

sensor_pin: analog10

control: watermark

#max_delta: 2.0

# On 'watermark' controlled heaters this is the number of degrees in

# Celsius above the target temperature before disabling the heater

# as well as the number of degrees below the target before

# re-enabling the heater. The default is 2 degrees Celsius.

min_temp: 0

max_temp: 110

# Print cooling fan (omit section if fan not present).

[fan]

pin: ar9

# PWM output pin controlling the fan. This parameter must be

# provided.

#max_power: 1.0

# The maximum power (expressed as a value from 0.0 to 1.0) that the

# pin may be set to. The value 1.0 allows the pin to be set fully

# enabled for extended periods, while a value of 0.5 would allow the

# pin to be enabled for no more than half the time. This setting may

# be used to limit the total power output (over extended periods) to

# the fan. If this value is less than 1.0 then fan speed requests

# will be scaled between zero and max_power (for example, if

# max_power is .9 and a fan speed of 80% is requested then the fan

# power will be set to 72%). The default is 1.0.

#shutdown_speed: 0

# The desired fan speed (expressed as a value from 0.0 to 1.0) if

# the micro-controller software enters an error state. The default

# is 0.

#cycle_time: 0.010

# The amount of time (in seconds) for each PWM power cycle to the

# fan. It is recommended this be 10 milliseconds or greater when

# using software based PWM. The default is 0.010 seconds.

#hardware_pwm: False

# Enable this to use hardware PWM instead of software PWM. Most fans

# do not work well with hardware PWM, so it is not recommended to

# enable this unless there is an electrical requirement to switch at

# very high speeds. When using hardware PWM the actual cycle time is

# constrained by the implementation and may be significantly

# different than the requested cycle_time. The default is False.

#kick_start_time: 0.100

# Time (in seconds) to run the fan at full speed when either first

# enabling or increasing it by more than 50% (helps get the fan spinning).

# The default is 0.100 seconds.

#off_below: 0.0

# The minimum input speed which will power the fan (expressed as a

# value from 0.0 to 1.0). When a speed lower than off_below is

# requested the fan will instead be turned off. This setting may be

# used to prevent fan stalls and to ensure kick starts are

# effective. The default is 0.0.

#

# This setting should be recalibrated whenever max_power is adjusted.

# To calibrate this setting, start with off_below set to 0.0 and the

# fan spinning. Gradually lower the fan speed to determine the lowest

# input speed which reliably drives the fan without stalls. Set

# off_below to the duty cycle corresponding to this value (for

# example, 12% -> 0.12) or slightly higher.

[printer]

kinematics: corexy

# This option must be "cartesian" for cartesian printers.

max_velocity: 500

# Maximum velocity (in mm/s) of the toolhead (relative to the

# print). This parameter must be specified.

max_accel: 3000

# Maximum acceleration (in mm/s^2) of the toolhead (relative to the

# print). This parameter must be specified.

#max_accel_to_decel:

# A pseudo acceleration (in mm/s^2) controlling how fast the

# toolhead may go from acceleration to deceleration. It is used to

# reduce the top speed of short zig-zag moves (and thus reduce

# printer vibration from these moves). The default is half of

# max_accel.

max_z_velocity: 25

# For cartesian printers this sets the maximum velocity (in mm/s) of

# movement along the z axis. This setting can be used to restrict

# the maximum speed of the z stepper motor on cartesian

# printers. The default is to use max_velocity for max_z_velocity.

max_z_accel: 30

# For cartesian printers this sets the maximum acceleration (in

# mm/s^2) of movement along the z axis. It limits the acceleration

# of the z stepper motor on cartesian printers. The default is to

# use max_accel for max_z_accel.

#square_corner_velocity: 5.0

# The maximum velocity (in mm/s) that the toolhead may travel a 90

# degree corner at. A non-zero value can reduce changes in extruder

# flow rates by enabling instantaneous velocity changes of the

# toolhead during cornering. This value configures the internal

# centripetal velocity cornering algorithm; corners with angles

# larger than 90 degrees will have a higher cornering velocity while

# corners with angles less than 90 degrees will have a lower

# cornering velocity. If this is set to zero then the toolhead will

# decelerate to zero at each corner. The default is 5mm/s.

[display]

lcd_type: hd44780

rs_pin: ar16

e_pin: ar17

d4_pin: ar23

d5_pin: ar25

d6_pin: ar27

d7_pin: ar29

encoder_pins: ^ar33, ^ar31

click_pin: ^!ar35

kill_pin: ^!ar41

[virtual_sdcard]

path: /home/octoprint/.octoprint/uploads

[homing_override]

gcode:

G28 Z

G28 X

G28 Y

#[gcode_macro START_PRINT]

#default_parameter_BED_TEMP: 55

#default_parameter_EXTRUDER_TEMP: 215

#gcode:

# CLEAR_PAUSE

# M140 S{BED_TEMP}

# M190 S{BED_TEMP}

# M109 S{EXTRUDER_TEMP}

# G90

# G28

# G1 X50 Y150 F2000

# G1 Z5 F1000

#

#

#[gcode_macro END_PRINT]

#gcode:

# TURN_OFF_HEATERS

# M106 S0

# G91

# G10

# G1 Z20 X-20 Y-20

# G90

# M84

## G10/G11 ###

#[firmware_retraction]

#retract_length: 5.8

#retract_speed: 80

#nretract_extra_length: 0

#nretract_speed: 80

# Looking for more options? Check the example-extras.cfg file.

Спойлер

Работа с TMC 2209 в Klipper

После включения принтера можно проверить подключение драйверов:

DUMP_TMC stepper=stepper_x

DUMP_TMC stepper=stepper_y

Консоль должна выдать что-то похожее:

Код: Выделить всё

Send: DUMP_TMC stepper=stepper_y

Recv: // ========== Write-only registers ==========

Recv: // IHOLD_IRUN: 00080c09 IHOLD=9 IRUN=12 IHOLDDELAY=8

Recv: // TPWMTHRS: 0000005e TPWMTHRS=94

Recv: // TPOWERDOWN: 00000014 TPOWERDOWN=20

Recv: // SGTHRS: 0000004b SGTHRS=75

Recv: // ========== Queried registers ==========

Recv: // GCONF: 000001c0 pdn_disable=1 mstep_reg_select=1 multistep_filt=1

Recv: // GSTAT: 00000001 reset=1

Recv: // IFCNT: 00000007 IFCNT=7

Recv: // OTP_READ: 0000000c OTP_FCLKTRIM=12

Recv: // IOIN: 21000041 ENN=1 PDN_UART=1 VERSION=0x21

Recv: // FACTORY_CONF: 0000000c FCLKTRIM=12

Recv: // TSTEP: 000fffff TSTEP=1048575

Recv: // MSCNT: 00000028 MSCNT=40

Recv: // MSCURACT: 00ef003c CUR_A=60 CUR_B=239

Recv: // CHOPCONF: 14030053 toff=3 hstrt=5 TBL=2 vsense=1 MRES=4(16usteps) intpol=1

Recv: // DRV_STATUS: c0090000 CS_ACTUAL=9 stealth=1 stst=1

Recv: // PWMCONF: c80d0e24 PWM_OFS=36 PWM_GRAD=14 pwm_freq=1 pwm_autoscale=1 pwm_autograd=1 PWM_REG=8 PWM_LIM=12

Recv: // PWM_SCALE: 0000000b PWM_SCALE_SUM=11

Recv: // PWM_AUTO: 000e0024 PWM_OFS_AUTO=36 PWM_GRAD_AUTO=14

Recv: // SG_RESULT: 00000000

Recv: ok

Подбираем свой driver_SGTHRS (0- выключено, 255 - очень чувствительный), и радуемся

Полезные ссылки

G-Code Klipper

Документация от Bigtreetech на tmc2209v2

п.с. Если гдето ошибся или указал неточно, поправьте, буду благодарен

п.п.с Всем бобра

Спойлер

Спойлер

Спойлер

Спойлер

Спойлер

Предыстория

Раньше ипользовал Repetier но т.к. он не поддерживает tmc2209 в режиме UART - решил перейти на Klipper...

Спойлер

Предыстория

Раньше ипользовал Repetier но т.к. он не поддерживает tmc2209 в режиме UART - решил перейти на Klipper...

Спойлер

Проблемы

Решил применить TMC2209 в режиме UART на оси X и Y с применением технологии stallGuard (без концевиков)

Спойлер

Проблемы

Решил применить TMC2209 в режиме UART на оси X и Y с применением технологии stallGuard (без концевиков)

Спойлер

TMC2209 BIGTREETECH v1.2 UART

Настройка klipper на работу с TMC 2209

Спойлер

TMC2209 BIGTREETECH v1.2 UART

Настройка klipper на работу с TMC 2209

Спойлер

Спойлер

Спойлер

Работа с TMC 2209 в Klipper

Полезные ссылки

Спойлер

Работа с TMC 2209 в Klipper

Полезные ссылки